Owlet Cam 2 is the company’s second generation baby monitor camera. With new features like cry notification and the ability to save & share video clips, we wanted to refresh the design to reflect these new product features. While keeping the internal architecture the same, we evolved the design language, reduced BOM costs, improved color matching between parts and different batches, and created 3 new color ways, the first in the baby camera category.

Scope of work included: developing new design language, CMF exploration, cost reduction exploration, process and quality improvements, review/approve DFMs and golden samples, develop/implement design and quality specifications, and manufacturing support. Launched summer of 2022.

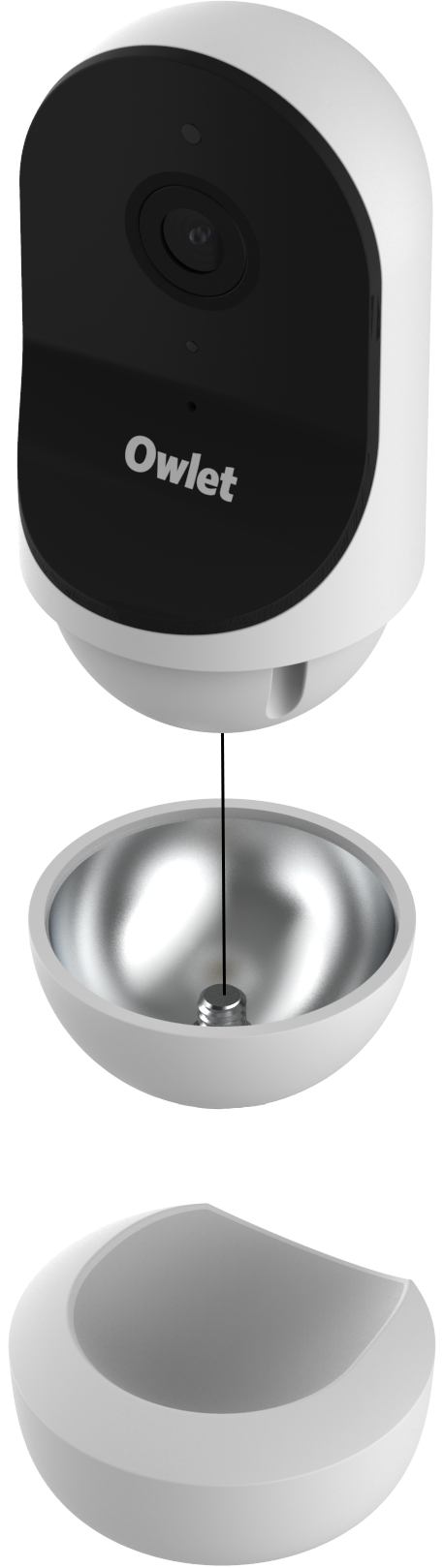

With compressed timelines and limited engineering resources, the pd team made the compromise of a refreshed look or facelift, versus a complete redesign. This meant sticking with the experience of a magnetic base and reusing the camera’s internal architecture so certain components like the lens assembly, PCB, and heat sink could be reused. Even with these heavy constraints, we set out to create a design that retained the fun and approachable feel of the first gen camera while giving it an updated look that is easily differentiable from its predecessor.

Gen 1

Gen 2

Besides updating the design, I led the effort to reduce the BOM costs and improve quality. On the 1st gen cam, we had problems matching the color and texture of the bottom housing to the top. The lower housing is stamped out of metal and painted to match the upper molded plastic housing. The metal was necessary for the camera to snap onto the magnetic base. On the 2nd gen cam, I suggested we mold a layer plastic over the metal instead of using paint (we updated the magnet in the base from a N52 to a N54 to accommodate this extra layer of plastic). Not only were we able to get a perfect color and texture match with this process, we were also able to improve yields and reduce costs associated with mixing, applying, and curing the paint. We also devised a new assembly method that did not require any visible screws. Now the bottom of the camera is perfectly smooth and color matched.

Gen 1. Painted stamped metal with visible assembly screw.

Gen 2. Molded plastic over stamped metal with internal assembly screw.

At Owlet, we believe that no two parenting journeys are the same. So with the gen 2 camera, we celebrated this by offering more than just a plain white colorway. We worked with sales & marketing and our retail partners to come up with 3 new color ways for the launch of our second gen camera. We developed a color story for both the camera and the camera’s accessories (we didn’t settle for white cables and white cable guards on a colored camera) and worked meticulously with our suppliers to make sure every part was color matched to our exact design specifications.

Left: We were having trouble color matching the painted metal bottom housing to the molded top plastic housing. This led to the idea to mold plastic over the metal bottom housing. Middle: Comparing molded bottom plastic housing to painted metal housing. Right: Color matching temperature sensor housing to camera housing.

Left: Color matching the pad print logo color which is unique for each colorway. Middle: Color matching the cable and cable guard, the color were intentionally less bold than the color of the camera. Right: Color matching base rubber pad. The rubber base pad is intentionally darker to hide dirt and remove the need to match the plastic color.